This introduces a case study using Contec solutions and products for a customer in the manufacturing industry.

The AGC Group provides application solutions for architectural, automotive, and display glass as well as chemicals and other high-performance materials to customers around the world.

Under its AGC plus 2.0 management policy, the AGC Group is committed to promoting Smart AGC, which aims to transform business processes through digital technology. AGC has been improving the efficiency of its business processes by introducing digital technology not only in manufacturing and R&D but also in such back-office operations as purchasing and logistics departments.

Keyword: Inspection | Industrial IoT

Industry: Manufacturing

Purpose: Work efficiency improvement | Manpower-saving | Quality improvement

Fuji Keisoku System’s automatic engine data sampling system is used in a wide variety of fields using engines from various manufacturers including those of automobiles, bicycles, automotive parts, construction and heavy machinery, and petroleum. This system uses a Windows computer with a Contec measurement and control interface board embedded in the expansion unit.

Keyword: Inspection | DAQ & Control

Industry: Manufacturing

Purpose: Space saving

Iwasaki Electric Mfg. Co., Ltd. developed Cyber Tester to help eliminate malfunctions from occurring. To achieve this, this system uses the Contec CTO-compatible controller. This is helping to enhance quality management.

Keyword: Inspection | Embedded PC | DAQ & Control

Industry: Manufacturing

Purpose: Space saving | Cost savings

Mitsuboshi Diamond Industrial Co., Ltd. is using high quality processing technology for various types of glass, establishing a process to work with various hard brittle material, and creating equipment and tools for that. Recent new product development placed an emphasis on realizing high-speed, high-precision laser processing technology and preventing the outflow of design and technology assets (by creating a black box for control technology). When we were searching for a trustworthy business partner with reliable technology, we came across the Contec controller. It has high performance, and our new product development took off.

Keyword: Control unit | Embedded PC

Industry: Manufacturing

Purpose: Enhanced features | Space saving

Nakamura Choukou Co., Ltd. manufactures and sells “DINA-PRISM”, a diamond saw wire cutting tool that is essential to the slicing process of electronic materials used for solar panels and LEDs. This company develops unique diamond wire technology. This technology is used to commercialize the slice processing of silicon ingots. A manufacturing execution system (MES) is used to manage this manufacturing process to improve their work efficiency and quality, and lower costs

Keyword: ERP MES

Industry: Manufacturing

Purpose: Cost savings | Manpower-saving | Work efficiency improvement

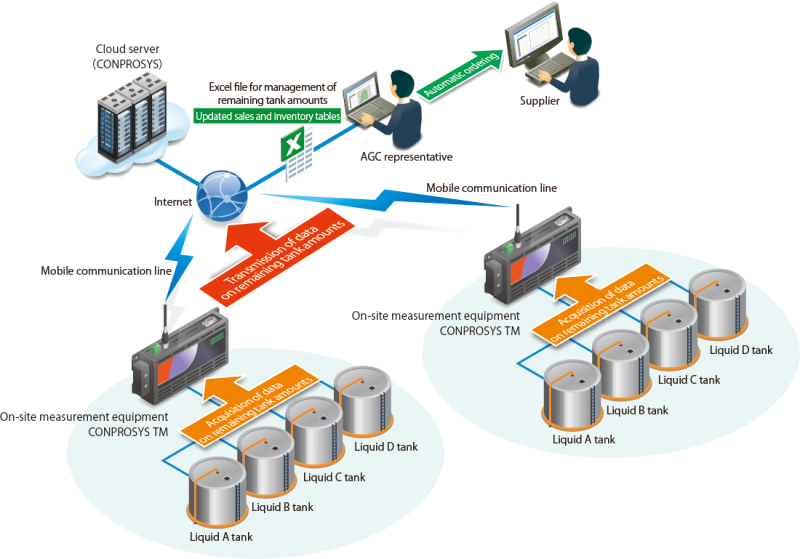

Contec implemented the CONPROSYS™ series of M2M/IoT Solutions developed in house to Komaki factory, which is the main base for Contec’s domestic production. The main purpose is to strengthen and enhance quality, cost, and delivery (QCD) by realizing visualization, and demonstrate the usefulness of Contec products. We are steadily obtaining results.

Keyword: ERP MES | Industrial IoT

Industry: Manufacturing

Purpose: Quality improvement | Cost savings | Enhanced customer service

CONTEC contributes to the growth of all industries though its original technology and manufacturing know-how. One example of that is our CONPROSYS™ series of industrial IoT solutions. Since 2015, we have been conducting demonstrations on the utility of our CONPROSYS™ series models at our company’s main factory, Komaki Office, with the goal of realizing and expanding various forms of “visualization.”

Keyword: ERP MES | Inspection | Industrial IoT

Industry: Manufacturing

Purpose: Quality improvement | Cost savings | Enhanced customer service