In recent years the manufacturing industry is considering new investments aimed at upgrading and optimizing factories and supply chains from a global view point to strengthen its presence in the globalization of business environment.

In factories, i.e. the bedrock of business, implementation of manufacturing innovations with IoT (Internet of Things) is required in accordance with development of Industrial IoT technologies in the world such like “Industry 4.0” proposed by German government and industries.

As a pioneer of the measurement & control by micro electronics, Equvera offers a vast lineup of reliable and high performance products that can support various sensors and actuators. Based on its expertise in highly reliable technology with electronic devices for factory automation since our establishment in 1975, we provide FA control equipment and systems that can optimize automation, research and development, production processes, and maintenance.

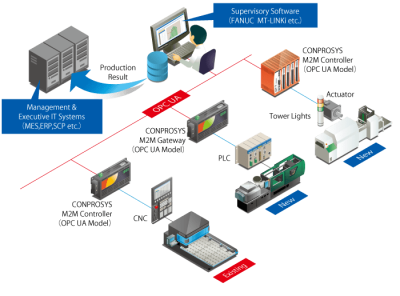

Equvera proposes IoT system based on open technologies that compliant with international standards such like open platforms and programming environments which are independent on specific manufacturers as well as field networks not depending on specific / proprietary communication protocols.

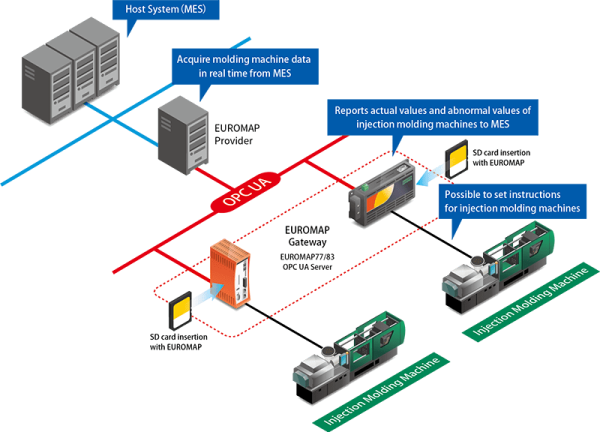

EUROMAP Gateway can connect to existing injection molding machines that do not support OPC UA or EUROMAP, interpreting the manufacturer’s proprietary communication protocols and data formats that differ from manufacturer to manufacturer, reducing the development time required for data integration with the host system.

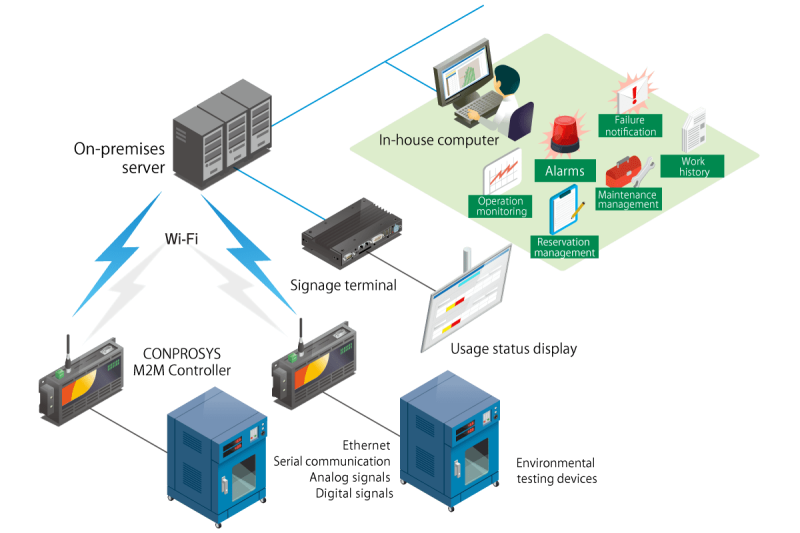

Using Contec’s IoT technology, operation management costs for environmental testing can be reduced and their operational efficiency enhanced. This enables all aspects of environmental testing—including operation monitoring, error notification, and reservation management—to be performed by connecting CONPROSYS™ IoT devices to X-ray testers, thermostatic chambers, vibration testers, and impact/drop testers and compiling all operational data in a server.

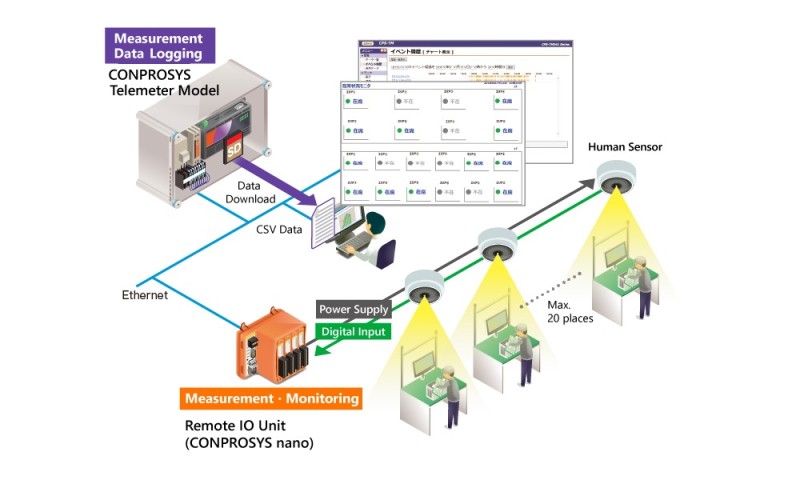

This is a system that manages the presence of cell production operators using Contec’s IoT technology. Install human sensors and IoT devices in the cell production area to collect human movement.

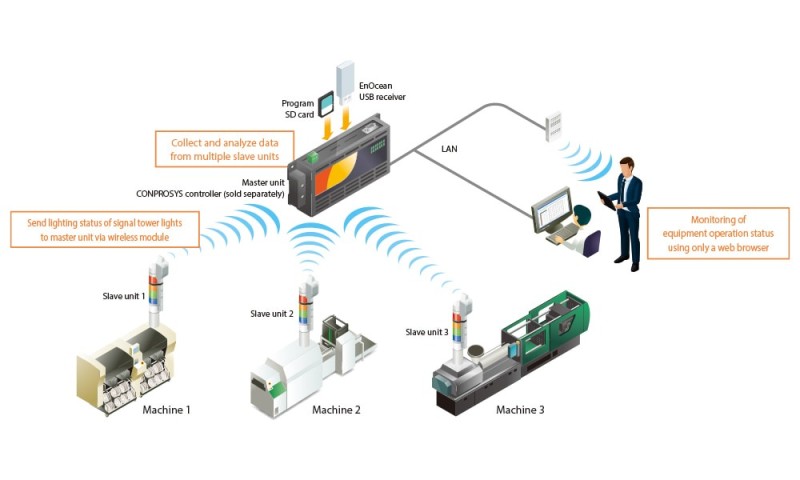

Signal towers make it possible to visualize current equipment operation statuses. Signal tower monitors are devices that monitor the lighting status of a signal tower and save the transmitted data. Devices (slave units) can be installed to signal towers already in use, with the simplest installation configuration taking only 10 seconds to complete.

This system enables improvement of production capacity of production line by status and achievement monitoring of all production facilities in the whole factory by connecting online existing, old-type facilities with new ones.

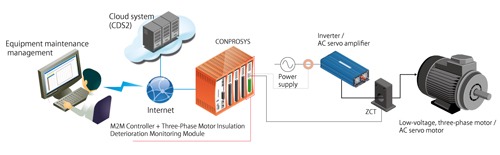

The Insulation Deterioration Monitoring Module from CONPROSYS™ is a revolutionary product for measuring the insulation resistance of three-phase motors that otherwise cannot be measured without stopping the device. With the CONPROSYS™ Insulation Deterioration Monitoring Module, constant motor insulation deterioration monitoring is possible for three-phase motors, allowing for detection of possible signs of failure.

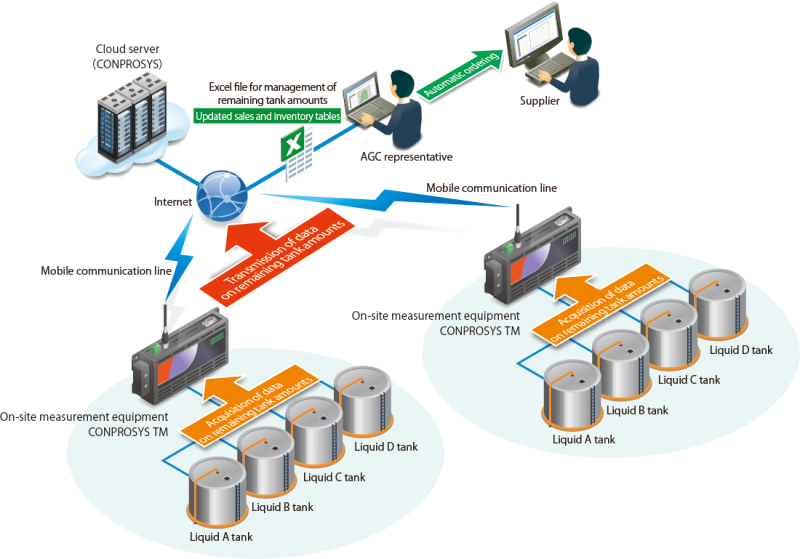

The AGC Group provides application solutions for architectural, automotive, and display glass as well as chemicals and other high-performance materials to customers around the world.

Under its AGC plus 2.0 management policy, the AGC Group is committed to promoting Smart AGC, which aims to transform business processes through digital technology. AGC has been improving the efficiency of its business processes by introducing digital technology not only in manufacturing and R&D but also in such back-office operations as purchasing and logistics departments.

Mitsuboshi Diamond Industrial Co., Ltd. is using high quality processing technology for various types of glass, establishing a process to work with various hard brittle material, and creating equipment and tools for that. Recent new product development placed an emphasis on realizing high-speed, high-precision laser processing technology and preventing the outflow of design and technology assets (by creating a black box for control technology). When we were searching for a trustworthy business partner with reliable technology, we came across the Contec controller. It has high performance, and our new product development took off.

Read More

Fuji Keisoku System’s automatic engine data sampling system is used in a wide variety of fields using engines from various manufacturers including those of automobiles, bicycles, automotive parts, construction and heavy machinery, and petroleum. This system uses a Windows computer with a Contec measurement and control interface board embedded in the expansion unit.

Read More

Iwasaki Electric Mfg. Co., Ltd. developed Cyber Tester to help eliminate malfunctions from occurring. To achieve this, this system uses the Contec CTO-compatible controller. This is helping to enhance quality management.

Read More

Nakamura Choukou Co., Ltd. manufactures and sells “DINA-PRISM”, a diamond saw wire cutting tool that is essential to the slicing process of electronic materials used for solar panels and LEDs. This company develops unique diamond wire technology. This technology is used to commercialize the slice processing of silicon ingots. A manufacturing execution system (MES) is used to manage this manufacturing process to improve their work efficiency and quality, and lower costs.

Read More

Contec implemented the CONPROSYS™ series of M2M/IoT Solutions developed in house to Komaki factory, which is the main base for Contec’s domestic production. The main purpose is to strengthen and enhance quality, cost, and delivery (QCD) by realizing visualization, and demonstrate the usefulness of Contec products. We are steadily obtaining results.

Read More